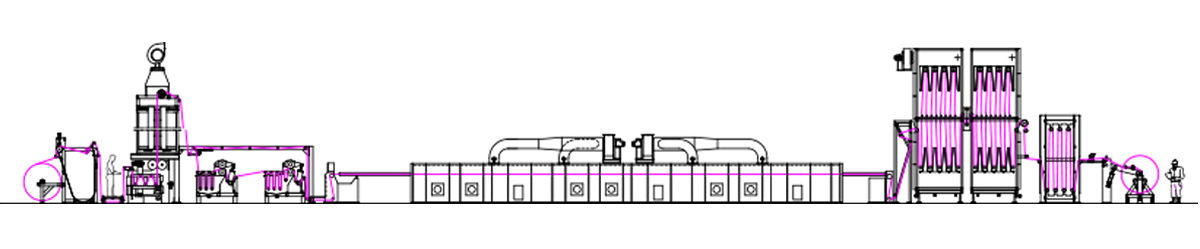

Nonwoven impregnation lines

On synthetic leather production, “coagulate” results to be one of the common used product. By a nonwoven impregnation process in a PU/MDF solution and subsequent immersion in water where the solvent precipitates and mixes, the “coagulated” PU is obtained in the non-woven fabric. Such technology allows to get a breathable substrate, which results important especially in shoes industry.This system is known as “wet process” because using a huge quantity of water.

Thanks to specific distillation equipment, solvent is separated from water in order to be re-used in the process.

In “Rotowet” family, you can find also “Rotowet Nonwoven” line Rotowet NonWoven equipment represent the closest Matex experience to the non-woven industry. This plant is specifically designed for the impregnation of needle punched and make it more structural stable for other processes. The process starts from a big diameter roll of needle punched non-woven (felt), which runs inside impregnation tank with water based compound, followed by drying and curing. The final product must then buffed and splits as per requirement. There are several application for such articles: hospitals, filtering, home cleaning…there are several finished products we use every day based on impregnated needle punched non- woven